Introduction

The RAD8 and RAD7 are capable of making direct measurements of radon-220 (‘thoron’) activity concentration in air. They do this by counting the decays of polonium-216 ions that have themselves been produced in thoron decays inside the measurement chamber. Thoron has a short (55.6 s) half life, so that much of the thoron in the sample will be lost during acquisition if the time from sampling to entering the measurement chamber and then leaving it is as much as a minute or more. It is therefore necessary that, when measuring thoron, the sample acquisition time should be as short as conveniently possible and always the same. Furthermore, for an absolute, calibrated measurement, exactly the same setup should be used for thoron calibration of the instrument as is used for thoron measurement.

Desiccant

A smoke detector works because the mobility of ions created inside the detector is reduced when they become attached to smoke particles. In a similar way, the mobility of polonium-216 ions inside a RAD8 or RAD7 measurement chamber is reduced in the presence of water molecules (humidity). Increased humidity increases the time it takes for the polonium-216 to be collected onto the central alpha detector, increasing the probability that they will be either neutralised or decay in-flight. The result in both cases is that the polonium-216 decays go unseen, decreasing the sensitivity of the instrument to thoron. Therefore, for highest efficiency and most precise measurements, it is recommended that Small Drying Tubes full of indicating desiccant be used to dry the air sample. These can be refilled with new or regenerated desiccant, or replaced with new tubes when exhausted. Measurement can still be made without desiccant, by using Capture software to download the data and plot readings corrected for humidity. However, this increases the measurement uncertainty, so it is always preferable to use desiccant where possible.

Thoron Measurement

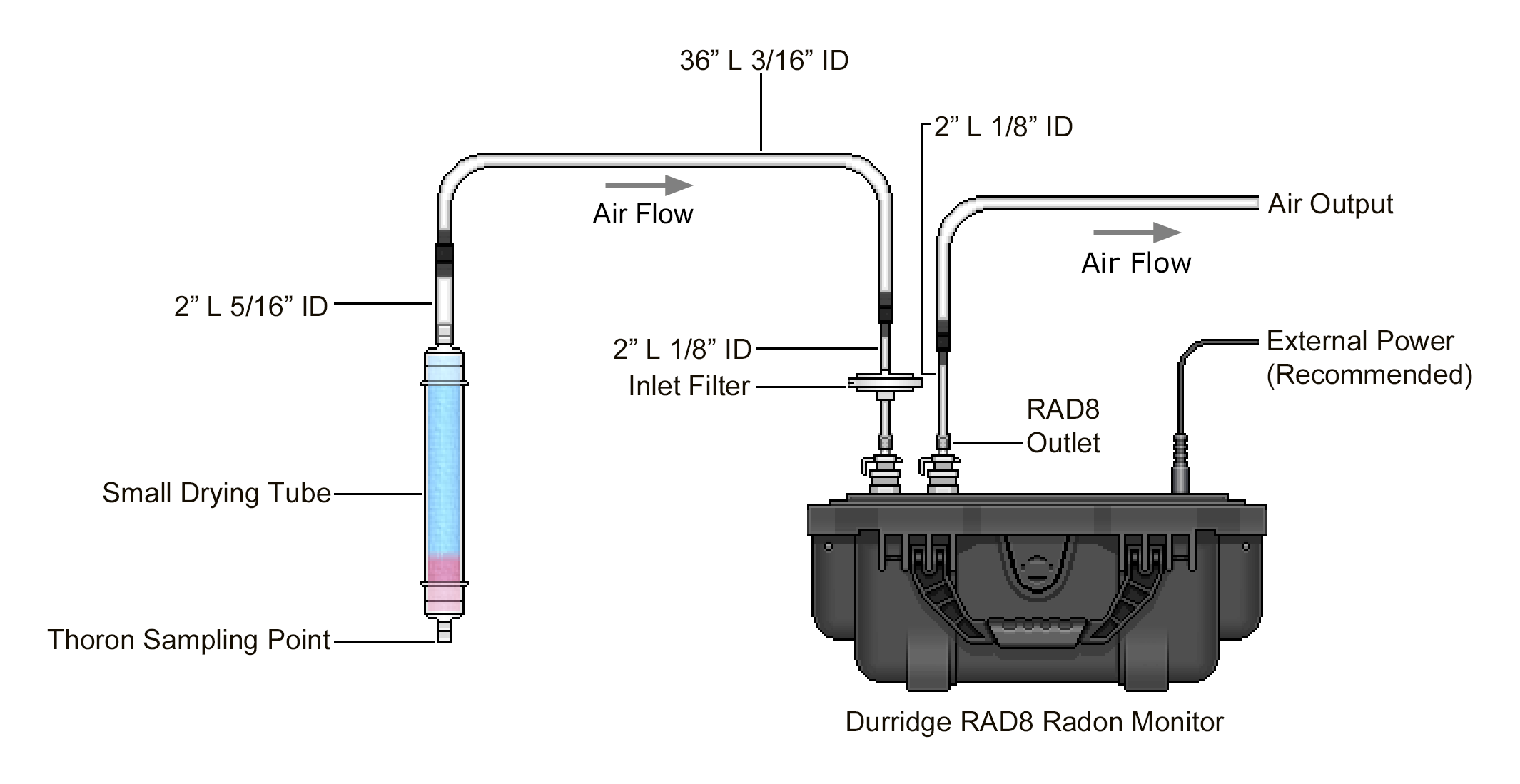

For a quantitative measurement of thoron, it is necessary to use a standardized setup and protocol. The setup assumed in the RAD8 and RAD7 data processing, and stated as standard in the manuals, consists of a Small Drying Tube (which may be used as a wand for sniffing) with a standard input tubing of 36″ (91.4cm) length and ID of 3/16″ (4.8mm); see below. This typically gives the RAD8 a thoron sensitivity of roughly 0.127 cpm/pCi/L, and the RAD7 a thoron sensitivity that is roughly half its radon Sniff sensitivity. The polonium-216 daughter of thoron has only a 145 mS half life, so the main component in the response time of the RAD8 or RAD7 to a step change in thoron concentration is the time taken to acquire the sample. The response is virtually instantaneous.

Figure 1: RAD8 Thoron Measurement Standard Setup

Thoron Calibration

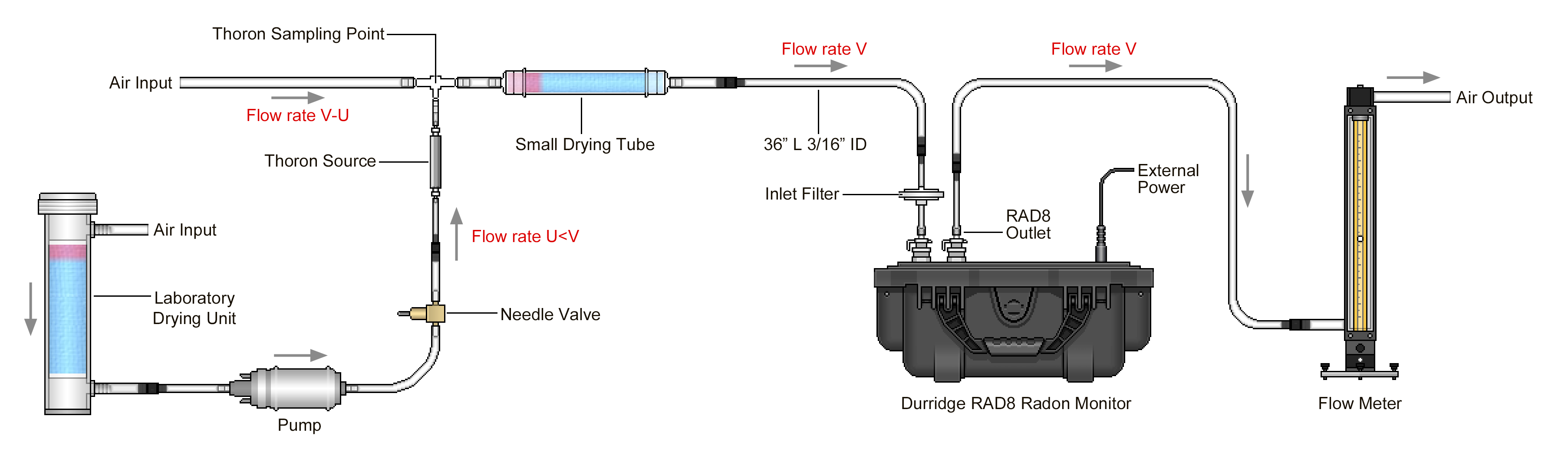

To calibrate a RAD8 or RAD7 for thoron, it is necessary that the setup be identical to that used for a thoron measurement, that the air flow rate, V, be the same as that used in a measurement, and that the thoron concentration be known at the sampling point. To achieve these criteria is not simple, but it is possible to come very close. The setup is as shown below:

Figure 2: RAD8 Thoron Calibration

The thoron source is attached close to a T-connector that, itself, is attached close to the end of the Small Drying Tube. The volume of air between the thoron source and the T-connector and between the T-connector and the end of the small tube are sufficiently small that the error from ignoring them is small compared with other uncertainties in the calibration.

The external pump that is used to inject thoron from the source into the RAD8 or RAD7 sample air flow, at the sampling point, is throttled by the needle valve so that the flow rate through the thoron source, U, is less than the RAD8 or RAD7 sample flow rate, V. When that condition is satisfied, we know that all thoron injected at that sampling point is carried towards the instrument and none of it leaks out through the fresh air inlet, that will have a fresh air flow rate in to the sampling point of (V – U).

Calculation

If S is the equivalent (actual times emissivity) source strength of the parent radium-224 in the thoron source, lambda (λ) the decay constant of thoron and V the flow rate of the RAD8 or RAD7, then:

λS = rate of injection of thoron into the RAD8 or RAD7 sampling point, and λS / V (with consistent dimensions) = Th, the thoron concentration at the sampling point.

If:

S is measured in Bq

λ = 0.0124 s-1

V is flow rate measured in L/min (= V/60 L/s), then

Th = 60 ⋅ λ ⋅ S/V Bq/L = 0.744 S/V Bq/L = 744 S/V Bq/m3

Note that the thoron concentration at the sampling point is inversely proportional to the flow rate, V. Increasing V will increase the RAD8 or RAD7’s sensitivity to thoron by reducing the fraction of thoron atoms that decay en-route to the measurement chamber, but it may not necessarily increase the reading during calibration, since the thoron output by the source per unit time is being diluted into a larger volume.

Note also that the thoron source’s output may depend on the humidity of the sample air. This effect should not be confused with the effect of humidity on the RAD8 and RAD7’s sensitivity. In fact, it works in the opposite direction, with increased humidity tending to increase the source emissivity and hence the equivalent source strength (S). A Laboratory Drying Unit upstream of the source maintains low-humidity conditions inside the source, and hence keeps the equivalent source strength stable.

Conclusion

A radium-224 thoron source of known strength and known emissivity may be used as described above to calibrate direct-reading thoron measuring instruments, such as the Durridge RAD8 and RAD7. Because of the significant sources of uncertainty both in the thoron calibration and in thoron measurements due, primarily, to the short half-life of thoron, conservative pessimism should be exercised in assessing the accuracy of the result.

A handful of laboratories around the world now offer SI-traceable thoron calibration, allowing a thoron calibration transfer standard to be used to determine the absolute equivalent strength of the thoron source in the above setup, albeit with a fairly high degree of uncertainty. With such a source, it becomes possible to calibrate an instrument for thoron. To use a calibration sensitivity, the instrument setup must be identical to that used in the calibration. Furthermore, the air flow rate must be the same as when the instrument was calibrated, so a flow meter is desired for the most precise work.

With an uncalibrated thoron source, it is still possible to compare the thoron sensitivity of two different instruments and, if the thoron source is fully supported and in equilibrium, to monitor the sensitivity of a single instrument over a period of time. For some applications, when using thoron as a short-lived tracer, as in locating radon entry points in a building, an absolute thoron calibration is irrelevant in that relative values of thoron concentration are all that are required.

Article PDF

View this article in PDF format:

Technical Note: Thoron Calibration (PDF)

Related Products

RAD8 Radon Monitor (HTML)

RAD7 Radon Monitor (HTML)

Related Services

Thoron Calibration Service (HTML)

Radon Calibration Service (HTML)